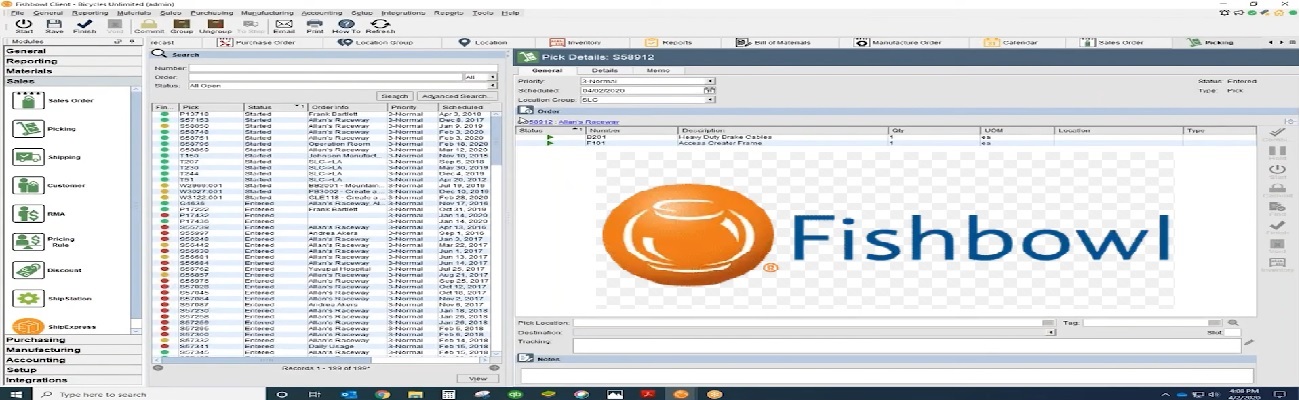

Fishbowl EDI Integration Services | Seamless ERP & Inventory Sync

Updated On 27 Sep, 2025

Reducing lead times, increasing perfect order rates, and automating processes are top priorities for modern logistics and supply chain managers. Achieving these benefits requires smart use of technology — but knowing where to start, the right steps to take, and challenges to expect can be overwhelming.

This guide walks you through building an effective data exchange system that connects your company’s product distribution (ERP) and warehouse management systems (WMS). We use a real-world example of switching warehouse service providers for a large international retail network specializing in branded clothing. The insights shared also apply across many industries.

When Should You Optimize Your Data Exchange System?

-

When changing warehouse service providers or ERP systems

-

When enhancing existing components, like automating warehouse services such as labeling or alerts

What Is EDI Integration and Why Is It Important?

Electronic Data Interchange (EDI) automates the exchange of standardized files (text, Excel, or other formats) based on a defined set of fields understood by both systems. The project manager’s role is to clearly define business needs and develop detailed assignments for IT teams, including test cases and functional requirements.

Core EDI and Warehouse Integration Processes

-

Goods Acceptance: Receiving and verifying goods upon arrival

-

Order Assembly: Picking and preparing orders for shipment

-

Shipment: Dispatching orders to customers

Understanding Different Item Types and Storage Methods

-

Piece goods stored in specific cells

-

Cross-docking for wholesale clients (items transferred directly without warehousing)

-

Point of Sale Materials (POSM) like packaging and display equipment

Some goods do not require separate storage but are tracked virtually using a "Status" flag. Examples include:

-

Returned or markdown items stored separately

-

Blocked goods, such as defective products restricted from shipment

-

Lost inventory items

Managing Inventory Discrepancies

Discrepancies between physical stock and system records happen. Assigning a "Lost by the Warehouse" status to missing items before inventory counts excludes them from order assembly, but if found, their status can be reverted to "For Sale."

Item Status Categories

-

Marriage (4)

-

Blocking (3)

-

Lost by the Warehouse (2)

-

For Sale (1)

Breaking Down Processes into Subprocesses

Create a detailed map (for example, an Excel sheet) outlining warehouse cargo handling steps for all items—this clarity is key to successful EDI system integration.

A) Acceptance Process

-

Warehouse receives acceptance tasks

-

Unloading and placing goods

-

Verifying quantity and quality, then assigning storage locations

-

Receiving confirmation and reporting discrepancies

B) Order Assembly

-

Receiving assembly tasks

-

Preparing waybills and picking items

-

Performing additional services as needed

-

Packaging, labeling, and printing packing lists

-

Moving orders to dispatch zones

-

Receiving assembly confirmation

C) Shipment

-

Loading vehicles

-

Printing shipment documents (waybills, bids, etc.)

-

Confirming shipment completion

EDI Message Flow

Because EDI messages are generally unidirectional, each subprocess should clearly define data transmission direction and the corresponding message type.

At Cogential IT, we make connecting with your EDI partners seamless. Our trusted solutions give you tighter control over warehouse EDI integration and complete visibility into your supply chain. This empowers you to accelerate and automate operations for maximum efficiency and measurable business impact.